Make Your Own Meths Burner

Captain Paranoia shows you how to make your very own

drinks can meths stove.

Posted: 31

July 2009

by Captain

Paranoia

Kevin Beeden, aka 'Captain Paranoia,

shows you how to make your own meths-burning DIY lightweight stove from a

drinks can.

There are many sets of instructions on the Web, such as at ZenStoves or AntiGravityGear.

Whilst the ZenStoves and AGG pages are useful to get an idea of how drinks can

burners are made, I think they both present fundamentally flawed designs; both

have joins in the middle of the burner which results in a weak structure. It's

far better to use the strong structures of the can to form a robust joint that

requires no glue. I also find the instructions over-complicated, using

templates, plaster-cast moulds and inelegant construction methods.

Here is my method for making a simple, Trangia-style, open-pot, top-jetting

burner. It requires no epoxy glue, no flue tape, and needs only a Stanley

blade, a craft knife, a straight edge and a thumb tack to make. It deliberately

avoids using templates, etc. and takes measurements from the can itself, so

that, provided you can remember the steps, you can make it anywhere. With

practice, it takes about 15 minutes to make.

Nb. These instructions assume you know how to use and handle sharp tools

safely, and how to use opposing muscle tension to control the movement of tools

whilst applying cutting force, and what protective equipment to wear; knife

blades can snap...

In case you can't guess from the photos, I'm left-handed. You might want to

re-arrange things if you're right-handed.

As with all things, it's worth reading through and understanding the

instructions before you start.

|

|

1. My

method is to insert a shorter, upper, inner part into a full-height lower,

outer part, and let the two parts guide the placement of the inner wall, and

then to remove the dimple of the upper can. |

|

|

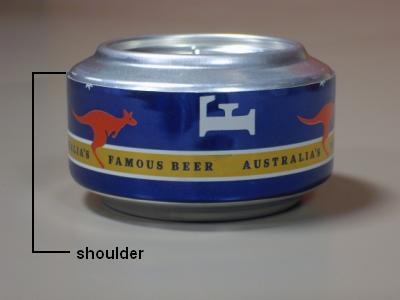

2. Start

with two identical aluminium cans. The pressed rings of the bases, and the

shoulders of the cans must be free from dents. |

|

|

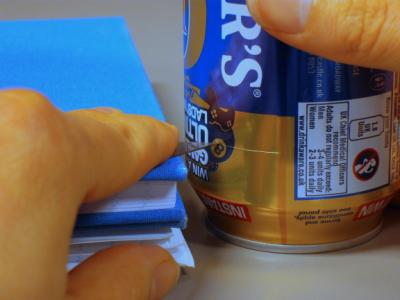

3. Press

the tip of the blade into the can by about 1/2" to start the cut. |

|

|

4. Flip

the can over and score and puncture the top half, in preparation for making

the inner wall. |

|

|

5. Remove

the base by using your thumbnail to make the can tear along the scoreline,

starting from the cut. |

|

|

6. Take

the second can and locate the ring of the pressed dimple that we'll remove

later. Whilst can designs vary, there's usually a distinct corner between the

wall of the pressed ring, and the curved bowl of the dimple. |

|

|

7. Make

four (or more) cuts from near the centre of the dimple to the dimple ring

(this will allow air to escape as we mate the two halves, and prepare for the

later removal of the dimple). |

|

|

8. Four

cuts completed. |

|

|

9. Using

the same measuring book, insert the Stanley blade between the pages, so that

it is about 3mm (1/8") below the cover*. We need the inner can to be

slightly shorter than the outer can to allow the burner halves to mate

properly. |

|

|

10. Now to

make the inner wall. |

|

|

11. Score

vertically up the side of the can through the height mark (so that the mark

appears on both edges) and then remove the top of the can by tearing along

the score (as for the base). |

|

|

12. Gently

fold along the vertical score to break the side wall open. |

|

|

13. Open

out the side wall and score with a straight edge aligned on the scored height

marks at each end. |

|

|

14. Fold

& snap along the scoreline to complete the cut. |

|

|

15. Roll

the side wall up and insert into the pressed ring of one of the cans. |

|

|

16. Unroll

the side wall and use a set square to score a line a fraction over half way

across the strip at each mark. If you don't have a set square to hand, you

can usually get it square enough by eye, as it's not that critical. |

|

|

17. Gently

bend and snap along the score line to open two slots. Don't bend the strip

beyond the cut. |

|

|

18. Use

the score, fold and snap method to trim the ends of the strip to about 12mm

(1/2") outside the slots. |

|

|

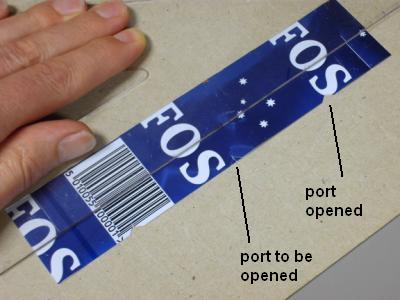

19. Cut

three little fuel ports around the base of the ring; they don't need to be

very big at all; 3mm (1/8") is fine. |

|

|

20. Mate

the two slots, with the ends facing the inside of the ring. |

|

|

21. The

inner wall is finished. |

|

|

22. Now we

need to expand the lower can to allow us to mate the two halves. |

|

|

23. Twist

the can base to remove it from the full can. |

|

|

24. Now to

mate the parts, for which we need a shim or 'shoehorn'. |

|

|

25. Place

the inner wall in the lower can, ensuring that the fuel ports are at the

bottom. |

|

|

26. Now

carefully press the shim side of the upper can down until the cans are

parallel, ensuring that the edges of the upper can remain inside the lower

can. |

|

|

27. When

the upper can is within the lower can, and they're roughly parallel,

carefully slide the shim out, holding the upper and lower cans in place. |

|

|

28.

Carefully press the two cans together. |

|

|

29.

Complete the insertion, pressing the cans together until the outer can

reaches the shoulder of the inner can, or you feel the resistance of the

inner wall meeting the two halves. |

|

|

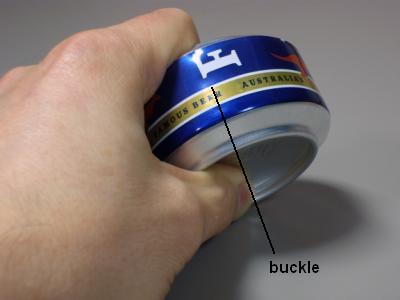

30. You

will usually find that the side wall of the inner can has buckled in one

place in order to squeeze into the lower can. You may even hear the can 'pop'

as this happens. |

|

|

31. The

dimple of the upper can is removed using the scoring method, but, due to the

thicker metal, and the curved edge, it's a little more difficult. |

|

|

32. Once

you have established a good score line, use the knife to extend the four cuts

we made earlier to the centre of the dimple, separating all the segments. |

|

|

33. Since

we can't risk inserting a knife into the scoreline, due to the possibility of

damaging the inner wall, we must use a tearing method instead. |

|

|

34. Clean

up the edges of the opening by scraping the edge of the knife blade along the

edge of the cut, taking care not to damage the inner wall. |

|

|

35. All

that's left is to prick or drill the jet holes, wherever you wish them to be. |

|

|

36. Mark

the jet positions with a strip of paper wrapped around the can, measured and

divided into regular gaps. |

|

|

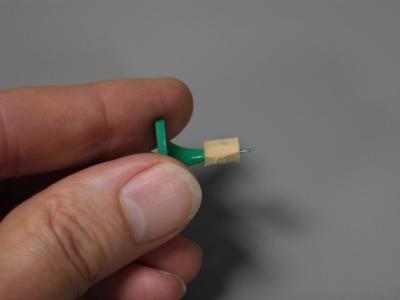

37.

Transfer the jet positions by reversing the template so that the marks are on

the inside of the ring, and are reflected onto the can. |

|

|

38. Drill

or prick the jet holes. There are many theories on the best position for the

holes, but putting them in the middle of the sloping section is very easy,

and minimises the chances of puncturing the inner or side walls. |

|

|

39. That's

it. Pour in a little meths and light up your burner. |

There's an

alternative build sequence that cuts out the dimple from the upper can at step

6, before the two halves of the burner are mated (score around the ring as in

step 31, but then use the knife to start the cut, and pop the entire dimple out

with a rounded tool, or your thumb). This makes removal of the dimple slightly

easier, and guarantees that the inner wall won't be damaged as you remove the

dimple. However, it does make mating of the two halves more difficult, as you

need to take care to ensure that the wall is seated in the upper pressed ring

as you press the two halves together; leaving the dimple in place until the

halves are mated allows the dimples to automatically align the inner wall.

There's an

alternative build sequence that cuts out the dimple from the upper can at step

6, before the two halves of the burner are mated (score around the ring as in

step 31, but then use the knife to start the cut, and pop the entire dimple out

with a rounded tool, or your thumb). This makes removal of the dimple slightly

easier, and guarantees that the inner wall won't be damaged as you remove the

dimple. However, it does make mating of the two halves more difficult, as you

need to take care to ensure that the wall is seated in the upper pressed ring

as you press the two halves together; leaving the dimple in place until the

halves are mated allows the dimples to automatically align the inner wall.

If you choose this sequence, one way to make sure the wall is aligned correctly

is to seat the wall inside the upper dimple ring, and fasten it in place with

sellotape before you start the mating process at step 25. Don't allow the

sellotape to extend down the side wall of the upper can. Remove the sellotape

when the two halves are fully mated.  If you need

to make a burner in the field (e.g. you get to camp and find that you've

forgotten your burner), you can use the method presented here to build a

burner.

If you need

to make a burner in the field (e.g. you get to camp and find that you've

forgotten your burner), you can use the method presented here to build a

burner.

You may have noticed that these instructions make no use of a ruler to measure

anything; measurements have been given, but these are intended for guidance,

not for exact measurement. If you really need to measure something, a compass

romer can be used. However, the difficult things to find in the field (besides

two cans) are a flat working surface to rotate the cans on, a suitable

height-measuring object and a straight edge. The base of a cookpot is usually

flat enough to provide a work surface to allow the can to rotate smoothly, and

a rummage through your kit will probably yield something that can be used to

provide a height reference. A book, a map cover, walking pole, tent pole or peg

could be used as a straight edge, with a bit of care.

An alternative way to score the cans is to wrap a piece of paper around the

can, and ensure the ends overlap so the paper is parallel to the sidewalls. You

can then use the edge of the paper to guide the scoreline; it's more difficult,

and may not give as neat a result, but it can be made to work. The inner wall

can be marked in this way, too; in fact, it's best to measure the base and

inner wall on one can before attempting to break either away from the can.

For pricking the jet holes, use a safety pin that's probably to be found in

your first aid kit. In a pinch, the tip of the blade can be used very carefully

to make small holes.

Finally, if you're really stuck for a burner in the field, and can't find two

cans and the items needed for this technique, the easiest burner to make is a

simple open cup; just hack the bottom off any can or similar metal container

that comes to hand. It'll work pretty well, even if it does burn a little

slowly. ![]() I've been

making drinks can burners on and off for about ten years. Along the way, I've

picked up ideas and tips from many sources, most of which I've probably

forgotten. So, whilst I've called this 'my method', it's only my method in so

far as it's the collection of techniques that I've adopted over the years. The

only bit that might be original is leaving the dimple cutting until after

assembly, discovered by accident after making burners at a BBQ, and forgetting

to cut the dimple out first...

I've been

making drinks can burners on and off for about ten years. Along the way, I've

picked up ideas and tips from many sources, most of which I've probably

forgotten. So, whilst I've called this 'my method', it's only my method in so

far as it's the collection of techniques that I've adopted over the years. The

only bit that might be original is leaving the dimple cutting until after

assembly, discovered by accident after making burners at a BBQ, and forgetting

to cut the dimple out first...

Read more: http://www.outdoorsmagic.com/gear-features/make-your-own-meths-burner/6227.html#ixzz0sG4CsSsZ